Features

1. High Temperature Resistance: One of the standout features of silicone coated fiberglass fabric is its ability to withstand high temperatures. With a continuous operating temperature range typically between -70°C to 260°C (-94°F to 500°F), it remains stable and functional even in extreme heat conditions. This makes it ideal for applications where exposure to heat is a concern, such as insulation wraps, welding blankets, and fire protection barriers.

2. Fire Resistance: Due to the inherent properties of fiberglass combined with the silicone coating, this fabric offers excellent fire resistance. It does not readily ignite and has low flammability, making it a preferred choice for applications requiring fireproofing materials, such as fire curtains, smoke curtains, and industrial safety blankets.

3. Chemical Resistance: Silicone coated fiberglass fabric exhibits remarkable resistance to a wide range of chemicals, including oils, solvents, acids, and alkalis. This makes it suitable for use in environments where exposure to corrosive substances is prevalent, such as chemical processing plants, oil refineries, and laboratories.

4. Weather Resistance: The silicone coating provides an additional layer of protection against weather elements such as rain, UV radiation, and ozone. This enhances the fabric’s durability and longevity, making it suitable for outdoor applications like protective covers, tents, and awnings.

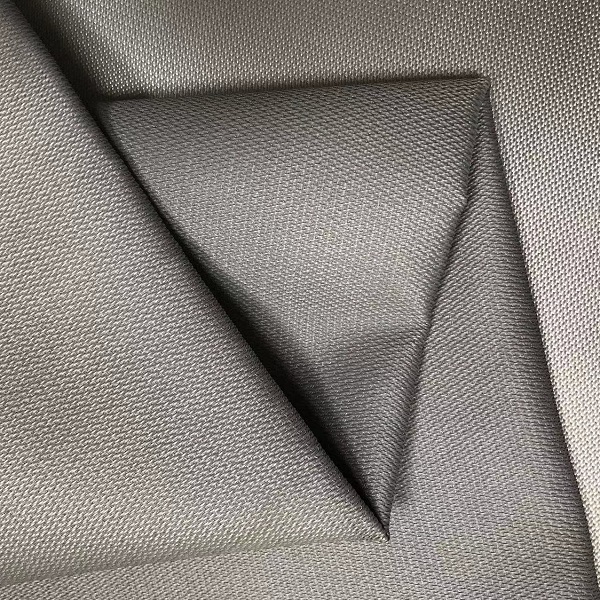

5. Flexibility and Durability: Despite its robustness, silicone coated fiberglass fabric remains flexible and pliable, allowing it to conform to various shapes and contours without compromising its structural integrity. This flexibility, coupled with its durability, ensures long-term performance in demanding applications, including flexible connectors, expansion joints, and gaskets.

6. Electrical Insulation: With its dielectric properties, silicone coated fiberglass fabric serves as an excellent electrical insulator. It prevents the passage of electrical current, making it suitable for applications requiring insulation from high voltage or electromagnetic interference, such as electrical insulation blankets, cable and wire wraps, and transformer insulation.

7. Non-Stick Surface: The silicone coating imparts a non-stick surface to the fabric, reducing friction and preventing adhesion of substances such as adhesives, resins, and food products. This feature is particularly advantageous in applications such as release sheets for composite manufacturing, baking mats, and conveyor belts in food processing.

8. Abrasion Resistance: Silicone coated fiberglass fabric exhibits high resistance to abrasion, ensuring durability even in environments where mechanical wear and tear are prevalent. This feature makes it suitable for applications involving repetitive motion or friction, such as conveyor belts, expansion joints, and protective sleeves.

9. Easy to Clean and Maintain: The non-porous surface of silicone coated fiberglass fabric facilitates easy cleaning and maintenance. It can be wiped clean with a damp cloth or washed with mild detergent, making it an ideal choice for applications requiring hygiene and cleanliness, such as food processing equipment covers and medical equipment insulation.

Application

1. Insulation Wraps: In industrial settings, silicone coated fiberglass fabric is commonly used as insulation wraps for pipes, ducts, and equipment exposed to high temperatures. It provides thermal insulation, protecting personnel and surrounding materials from heat transfer.

2. Welding Blankets: Due to its high temperature resistance and fire retardant properties, silicone coated fiberglass fabric is utilized as welding blankets to shield adjacent areas from sparks, spatter, and heat generated during welding operations.

3. Fire Protection Barriers: Silicone coated fiberglass fabric is employed in the construction of fire protection barriers and curtains to contain and prevent the spread of fire in buildings, vehicles, and industrial facilities.

4. Chemical Processing Equipment: In chemical processing plants, silicone coated fiberglass fabric is used in the construction of gaskets, seals, and flexible connectors due to its chemical resistance and ability to withstand harsh environments.

5. Oil and Gas Industry: In the oil and gas industry, silicone coated fiberglass fabric is utilized for thermal insulation wraps, fireproofing blankets, and protective covers for equipment and pipelines operating in extreme temperatures and corrosive environments.

6. Aerospace and Automotive: Silicone coated fiberglass fabric finds applications in aerospace and automotive industries for manufacturing heat shields, engine insulation, and protective covers due to its lightweight, high temperature resistance, and durability.

7. Marine Industry: In the marine industry, silicone coated fiberglass fabric is used to fabricate heat-resistant curtains, insulation blankets, and protective covers for engines, exhaust systems, and equipment onboard ships and offshore platforms.

8. Electrical Insulation: Silicone coated fiberglass fabric serves as electrical insulation in electrical equipment, transformers, and switchgear, providing protection against high voltage and electrical hazards.

9. Food Processing: In food processing facilities, silicone coated fiberglass fabric is employed as conveyor belts, baking mats, and release sheets due to its non-stick surface, high temperature resistance, and ease of cleaning.

10. Composite Manufacturing: Silicone coated fiberglass fabric is used as release films and vacuum bags in composite manufacturing processes to facilitate the removal of finished parts from molds and provide a smooth surface finish.

11. HVAC Systems: In HVAC (heating, ventilation, and air conditioning) systems, silicone coated fiberglass fabric is utilized as duct insulation, expansion joints, and seals to improve energy efficiency and prevent air leakage.

12. Personal Protective Equipment (PPE): Silicone coated fiberglass fabric is incorporated into personal protective equipment such as heat-resistant gloves, aprons, and suits worn by workers in high-temperature environments.

13. Tents and Awnings: Due to its weather resistance and durability, silicone coated fiberglass fabric is used in the manufacturing of tents, awnings, and outdoor shelters for recreational and commercial purposes.

14. Medical and Healthcare: In medical and healthcare settings, silicone coated fiberglass fabric is employed for insulation wraps, sterilization trays, and thermal blankets due to its non-toxicity, cleanliness, and resistance to sterilization processes.

Specification

| Item No. |

Thickness (mm) |

Width (mm) |

Color | Coating |

Total Weight |

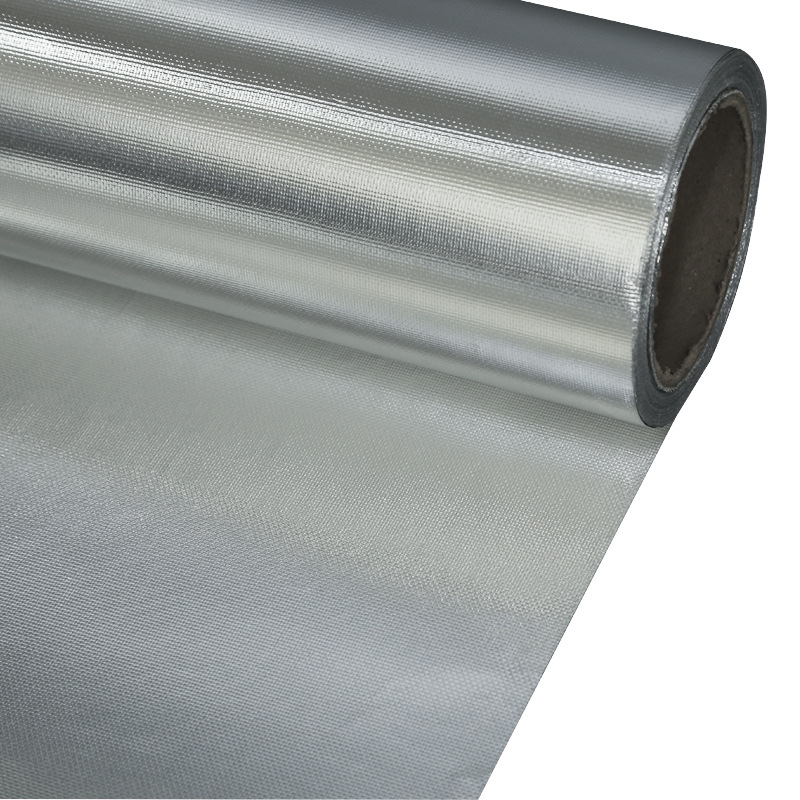

| FH2116E-100G2 | 0.15 | 1270 | Grey/Black | 50gx2 Side | 205g/m2 6oz/yd2 |

| FH7627E-130G2 | 0.22 | 1270 | Grey | 65gx2 Side | 330g/m2 9.7oz/yd2 |

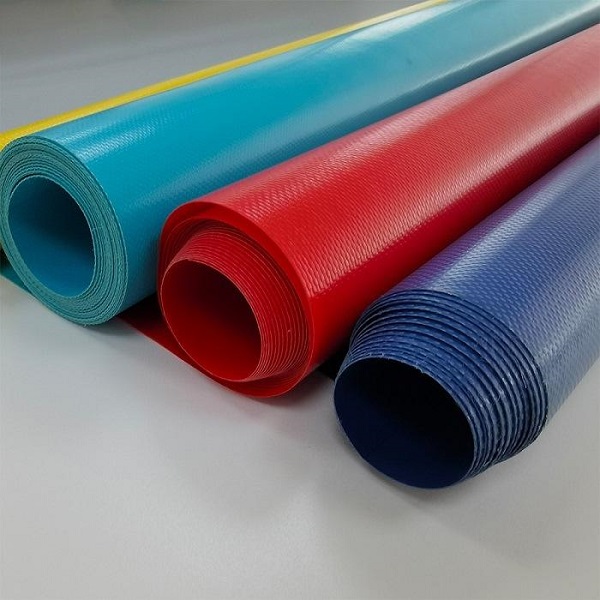

| FH3732E-80G1 | 0.43 | 1000/1550 | Grey/Red | 80gx1 Side | 510g/m2 15oz/yd2 |

| FH3732E-130G2 | 0.45 | 1000/1550 | Grey/Red | 65gx2 Side | 560g/m2 16.5oz/yd2 |

| FH3732E-200G2 | 0.45 | 1000/1550 | Grey/Red | 100gx2 Side | 630g/m2 18.5oz/yd2 |

| FH666E-150G1 | 0.68 | 1000/1520 | Grey/Red/Black | 150gx1 Side | 810g/m2 23.8oz/yd2 |

| FH666E-260G2 | 0.70 | 1000/1520 | Grey/Red | 130gx2 Side | 920g/m2 27oz/yd2 |

| FH3784E-260G2 | 0.90 | 1000/1520 | Grey/Red | 130gx2 Side | 1140g/m2 33.5oz/yd2 |